Is part of a pioneering ZIM cooperation project, AutoRobXL is developing a groundbreaking automation kit that will revolutionize the way we think about positioning and controlling attachments.

The challenge:

Until now, modular, autonomous and semi-autonomous positioning systems for mobile machinery were not available. This meant that every automation solution was tailor-made and therefore expensive and time-consuming.

Our solution:

This is exactly where AutoRobXL’s modular automation system comes in. We are developing a modular system that can be flexibly adapted to different machines and attachments. This makes automation affordable and accessible even for medium-sized companies with small production runs.

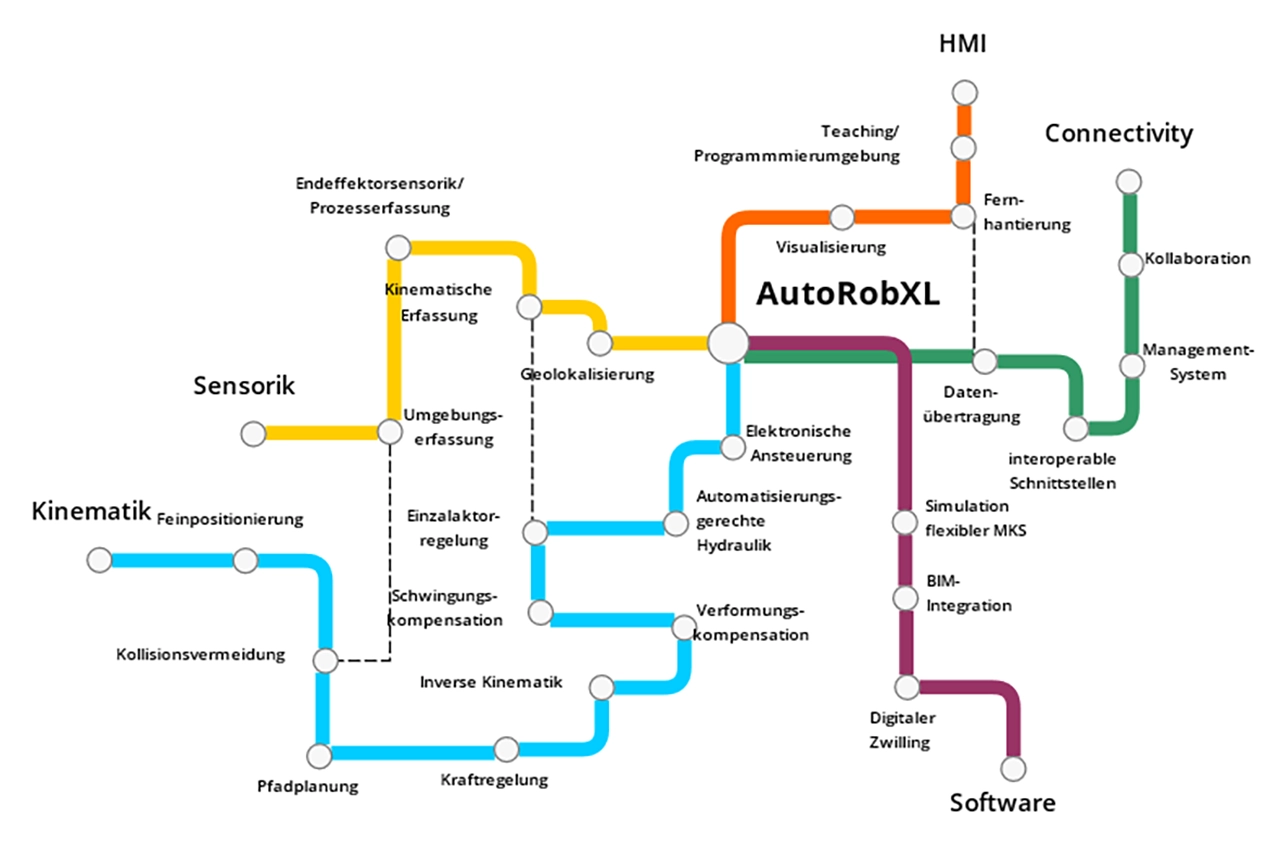

Central functions:

(Partially) automated positioning of the Tool Center Point (TCP): Precise and efficient control of the attachment for optimum work results.

Intuitive display and operating concept: The machine operator always retains full control and can visualize and control the positioning process in real time.

The advantages:

- Flexibility: The modular system can be adapted to different machines and tasks.

- Efficiency: Automated processes save time and resources.

- Precision: The TCP is positioned exactly, which increases the quality of the work.

- User-friendliness: The intuitive operating concept makes work easier.

- Affordability: Also accessible for medium-sized companies.

The future of automation:

With the AutoRobXL modular automation system, we are pioneers in the development of flexible and affordable automation solutions for mobile machinery. We look forward to shaping the future of the industry and offering our customers innovative solutions.

About AutoRobXL

The ZIM innovation network AutoRobXL pursues the goal of realizing automated work processes using mobile work machines and large-scale manipulators. Large-capacity manipulators are often long, elastic boom structures, some of which are subject to strong deformations and vibrations. Examples include truck-mounted concrete pumps, mobile cranes and cherry pickers. High movement accuracy and precise positioning of such structures are already important for manual work and are essential for the automation of the associated work processes. As part of the network, new solutions are therefore to be developed that enable the precise positioning of corresponding boom structures and the associated work tools. Building on this, we want to gradually expand the AutoRobXL innovation network website into a developer platform for the automation of large construction machines.

AutoRobXL

AutoRobXL automates the construction site

Objective

The development of intelligent control and operating concepts for construction machinery booms and large-scale manipulators to enable precise positioning and automation of work processes on construction sites.

Network partners

The AutoRobXL network partners:

- AMR-Hydraulik Chemnitz GmbH

- ATLAS GmbH

- Eckerle Technologies GmbH

- GEMAC Chemnitz GmbH

- Günter Till Präzisionsmechanik GmbH

- Hermann Paus Maschinenfabrik GmbH

- HYDAC Group

- Hydrive Engineering GmbH

- IBL-HYDRONIC GmbH and Co.KG GmbH & Co. KG

- MOBA Mobile Automation AG

- SCHWING Group

- Weiss Mobiltechnik GmbH

Research facilities:

- Dresden University of Technology with the chairs:

- Professorship for Construction Machinery

- Professorship for Fluid-Mechatronic Systems Engineering | Fluidtronics

- Chair of Machine Tool Development and Adaptive Controls (LWM), TU Dresden

- Professorship for Electrical Machines and Drives

The developer platform for the automation of large construction machines

The AutoRobXL network manager is Whiterock AG in Stuttgart. AutoRobXL is funded by the Central Innovation Program for SMEs (ZIM) of the Federal Ministry of Economics and Climate Protection (BMWK) in a first funding period from August 2023 to July 2024. The AutoRobXL network cordially invites all interested companies and developers to participate in phase 2, which started on 1.11.2024.

Further information can be found on the official website: autorobxl.de